Contract manufacturing and 3D printing

What are the advantages of contract manufacturing and how can 3D printing help you with that?

Login

If you have any trouble logging in to your account, contact us.

Sign Up

To start 3D printing or Laser Cutting, you'll need to create an account here. Once done, you'll be able to upload your files and get live quotes of yours parts

Already have an account? Log In

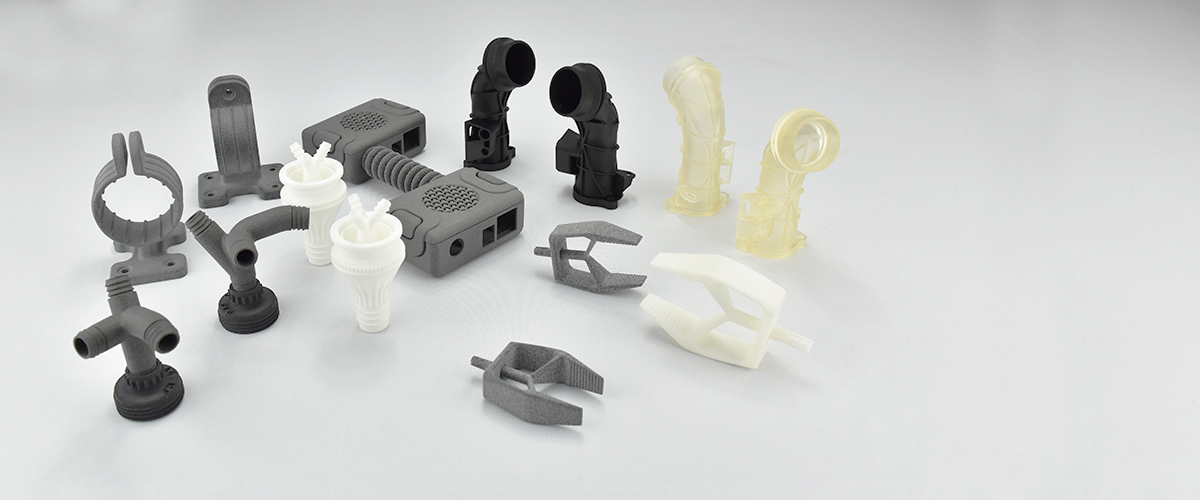

Have you ever thought about using 3D printing for contract manufacturing? Additive manufacturing can be the most efficient way to mass-produce your parts. From 1 to 10,000 units, this digital manufacturing technology can help you rethink your production by adding more freedom and flexibility without sacrificing quality.

With 10 years of experience in consulting and innovation, Arnaud Brachet and Arnaud Le Cat have focused on revolutionizing team building and training with an interactive business game, UWTI. Their mission is simple, reinvent and innovate the way of managing and working for today’s workforce. At first, 3D Printing was only to prototype their innovative boxes. After seeing the parts’ quality, they decided to produce and launch their first series on the market with Sculpteo.

Contract manufacturing is a cost-saving technique offering high-quality materials for your most demanding projects. Try these materials for your scaled additive manufacturing production:

Choose your contract manufacturer wisely. By choosing a 3D printing service bureau such as Sculpteo, you will benefit from:

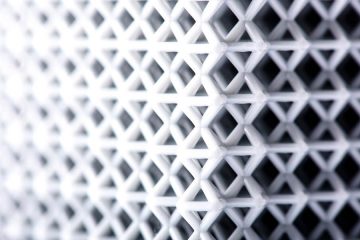

Using an online service bureau such as Sculpteo, there is no minimum order quantity, from a single object to 10 000+ parts, you can 3D print the exact amount of parts you need. With 10+ years of expertise in additive manufacturing for production and prototyping, Sculpteo is also offering rigorous quality control. With our online 3D printing service, you get professional 3D printing at your fingertips with +75 materials and finishes to develop your most ambitious projects. Create a free account and upload your 3D files, select your material, technology, and post-processing options, and order online.

We’ll take care of the rest in our industrial ISO 9001 factory.

Many companies are choosing to outsource manufacturing to reduce cost, benefit from the expertise and advanced skills of manufacturers, and get the quality control they expect for their products. These manufacturing companies will be manufacturing your products. Contract manufacturers can be involved in industrial, electronics, aerospace, medical devices and many more applications. Contract manufacturing is a cost-saving technique, this way you don’t have to invest in facilities, advanced equipment, or production staff and offers the opportunity to finally access perfectly scaled production! Indeed, these professional manufacturers are used to changing batch sizes, while maintaining high quality and efficiency. They are mastering their technologies, methodologies, and are specialists when it comes to scaling up a production.

Get to know more about 3D printing applications and how this game-changing manufacturing technique now becomes a real alternative to traditional manufacturing.

What are the advantages of contract manufacturing and how can 3D printing help you with that?

Follow the guide and get ready to be inspired by these business model ideas. What is changing exactly in your business strategy while choosing to implement additive manufacturing?

How to identify 3D printing opportunities for your business? Find out our 10 best tips and see how 3D printing could be a great asset for your business!

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook