Home » 3D Printing Materials » SLS technology » Nylon 3200 GF

Nylon 3200 Glass-filled 3D printing material

3D printed using the SLS technology, our Nylon 3200 Glass-filled is a mix of polyamide powder and glass fibers. Get all information to help you print your 3D model in our Nylon 3200 Glass-filled (plastic) material.

Colors

Finishes

Characteristics

Nylon 3200 Glass-filled Material Guide

What is Nylon 3200 Glass-filled?

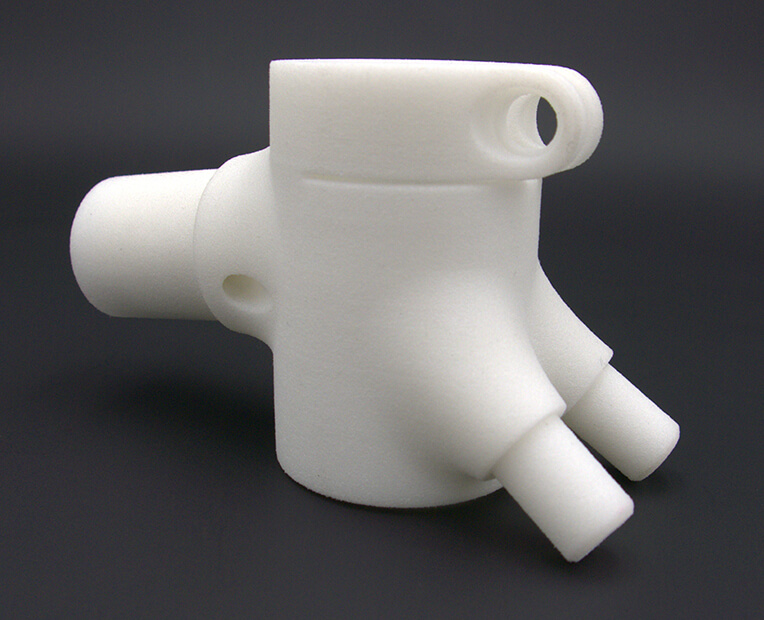

Objects printed in Nylon 3200 Glass-filled (glass-filled nylon) are made from a mix of polyamide powder and glass fibers. The surface of this 3D printing material is white and slightly porous. Our Nylon 3200 Glass-filled (glass-filled polyamide) is more durable and resistant than Nylon PA12.

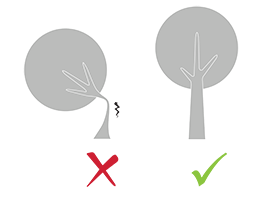

Using this engineering thermoplastic for 3D printing gives you great freedom in your designs – allowing for both complex and inclosed volumes. The material is great for technical parts that need resistance and loads. The surface of Nylon 3200 Glass-filled (glass-filled nylon) is not as accurate as Nylon PA12 but it will fit the requirements of technical parts. Glass-filled nylon has some good mechanical properties.

What is Glass-filled Nylon used for?

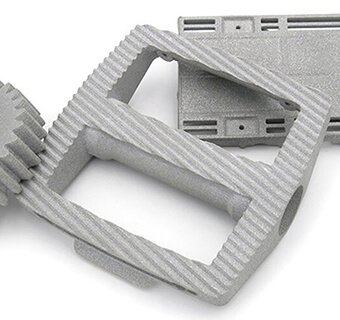

Glass-filled Nylon is mainly used for technical projects, which makes it really popular in industries such as the automotive sector. Indeed, Nylon 3200 Glass-filled (glass-filled nylon) is a great 3D printing material that allows for creating complex and resistant 3D printed models. It is durable and strong that’s why it perfectly fits technical uses. Thanks to its strength and rigidity, it can be placed near engines and used for parts that require a lot of stresses and loads; making it perfect for the automotive industry or to create any machine parts. The construction industry also uses this reliable material to produce complex and detailed structures.

Complex models can be 3D printed in glass-filled nylon, just as enclosed volumes. However, keep in mind that the surface of the glass-filled polyamide 3D printed objects is limited to 100 µm that means fine details will not be optimally printed. Nylon 3200 Glass-filled (glass-filled nylon) is indeed an engineering material that is used for technical parts that require particular stiffness, high heat distortion temperature and low abrasive wear, which is a good solution if you are looking for an alternative to parts created using plastic injection.

The surface quality of the Nylon 3200 Glass-filled (glass-filled nylon) is excellent and designed for uses in dirty environments. It is mainly used for parts with requirements on abrasion and wear, stiff housings, parts used under elevated thermal conditions (for example for final parts within the engine area of cars), for deep-drawing dies, or for any other application which requires particularly high heat distortion temperature, low abrasive wear, and special stiffness.

Glass-filled nylon also has good processability and excellent long-term constant behavior. All these good mechanical material properties make this material a really good choice for robust final parts.

Pricing

The printing price of your design is calculated automatically the moment it is uploaded. As you modify your object (changing material, finishing, size, using batch control or hollowing feature, etc.) you will note that the price changes automatically. The pricing is based on a series of factors, including total volume, object size, and bounding box – to name a few.

Keep in mind that adding finishing will extend the processing time. The estimated shipping time is also calculated automatically as the object is uploaded and each time you make a modification on it. Delivery time should be added to processing time.

For more information, check our pricing page.

What is the 3D printing process for Nylon Glass-filled?

Nylon 32000 Glass-FIlled is printed using Selective Laser Sintering. The SLS printing process uses a highly specific laser that sinters thin layers of our glass reinforced nylon powder together one layer at a time. After each round of lasering, the printing bed is lowered and another layer of powder is evenly swept across the top for another round of sintering. This process is repeated until the object is completed.

What are the finishing options for our Nylon 3200 Glass-filled?

There are two finishing options for Nylon 3200 Glass-Filled:

- Raw: sandblasted but unpolished, surface remains somewhat rough, this is the most economical option for this 3D printing material.

- Polished: polished through mechanical polishing, smoother to touch, layers still somewhat visible on rounded objects.

Standard layer thickness: 100 µm

Accuracy : ± 0.45% (minimum of ± 0.45 mm)

| Maximum size white/unpolished | 190 mm x 240 mm x 315 mm (7.48 in x 9.45 in x 12.40 in) |

| Maximum size polished | 180 mm x 150 mm x 150 mm (7.08 in x 5.91 in x 5.91 in) |

The maximum size of your models are limited by the physical size of our 3D printers – nothing can be printed larger than the printer bed or the one of our mechanical polishing machine. Your object must also respect the minimum dimensions of Nylon 3200 Glass-filled 3D prints (explained below).

| Minimum wall thickness (flexible) | 1.5mm |

| Minimum wall thickness particular design aspects | 2mm |

The walls of your design must adhere to a minimum thickness of 1.5mm in order to guarantee the structure will not break. If the walls of your model are less than 1.5mm, you can add a support structure to maintain stability.

For an object that is sure to be solid, a minimum thickness of 2 mm is recommended.

Sculpteo offers an online solidity check tool which highlights parts of the print that may be too thin for a print. From there you are able to tweak your design in order to create an object that is an appropriate thickness. To use it, you just need to upload your 3D file, select your material and click on “Verification” tab.

It is also important to keep in mind that the object is to be printed into real life. Thus if a thin aspect is supporting something that is too heavy for it, it may break – even though it is possible within the physics provided by your 3D modeling software. We recommend adding a bit of thickness to the places that will get a lot of handling, or that support the most weight.

Do not forget

Keep in mind that our solidity check tool does not detect physical aberrations such as floating parts, unstable position, parts supporting too much weight relative to their thickness, etc. Particular care must be given to the geometry of your design and the most stressed parts must be thickened.

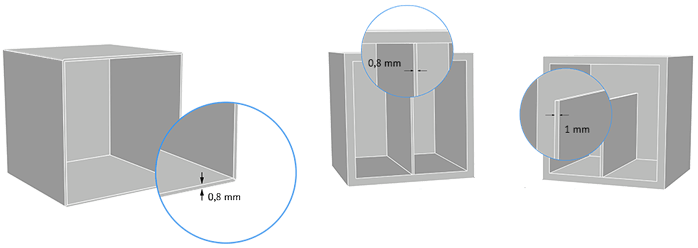

| Minimum size of details | 1 mm |

| Minimum size of text | 1 mm |

| Enlargement ratio | 1/1 |

A detail’s minimum precision is mainly determined by the resolution of our printers. However, during the cleaning process, a fine layer of detail can also be lost. In order for a detail and text to be visible we recommend following our recommended sizes at the very least. To ensure a better powder removal (thus a better detail precision), the width of your details must be at least as big as depth.

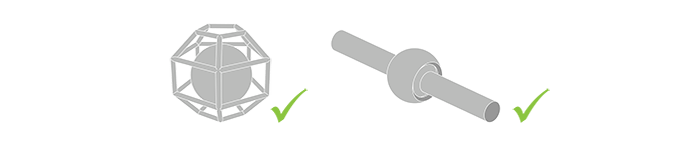

| Enclosed parts ? | Yes |

| Interlocking parts ? | Yes |

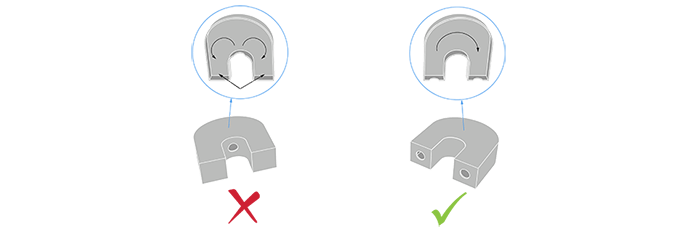

Our Nylon 3200 Glass-filled (glass-filled nylon) material has the ability to be printed for some complex designs. An example of a complex design is a volume enclosed within another volume or with articulations. Our glass-filled Nylon 3D printers have the ability to print a fully interlocked object out of the printer, with no support structures to remove.

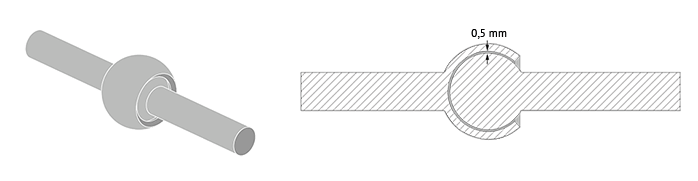

| Minimum spacing between fixed walls | 0.5 mm |

| Minimum clearance between parts | 0.5 mm |

For a successful 3D print a minimum clearance between objects is required to allow the excess of material to be sand blown out. If this space is not left within the design, the object will be a solid. This is particularly important for articulated objects – as the space left between the walls will define the object’s ability to move.

Clearance should be at least 0.5 mm and depends on your object’s size. For big sizes, the clearance should be greater. The heated zone of your object depends on the size, the larger the object the more time it will be exposed to high temperature: if the space left between the walls is too small, it will be weld because of heat spreading.

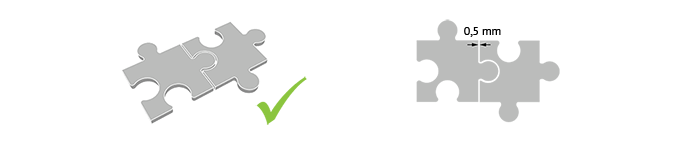

| Assembly ? | Yes |

| Minimum space | 0.5 mm |

Objects printed in Nylon 3200 Glass-filled can be printed to be assembled. As long as a width of at least 0.5 mm is left between the different parts of the object.

| Hollowing ? | Yes |

Our online hollowing optimization tool has the ability to greatly reduce the price of a print by reducing the amount of material used.

Using the tool requires adding two holes to your model, which will serve as the drain for the excess powder material within the object. The minimum size of these holes is determined by our website. Otherwise it is possible to hollow your object manually in your 3D modeling software.

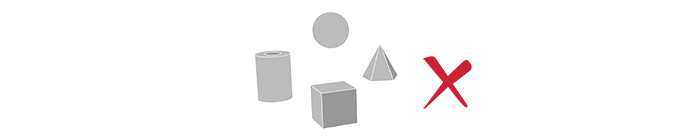

| Files with Multiple Objects? | No |

It is not possible to 3D print a 3D file containing several objects with Nylon 3200 Glass-filled (glass-filled nylon).

Ready to 3D print with Nylon 3200 Glass-filled?

With Sculpteo’s online 3D printing service you’re just a few clicks away from professional Nylon 3200 Glass-filled 3D printing. Your 3D model is printed with the highest quality and delivered straight to your door.

Get started now!

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook