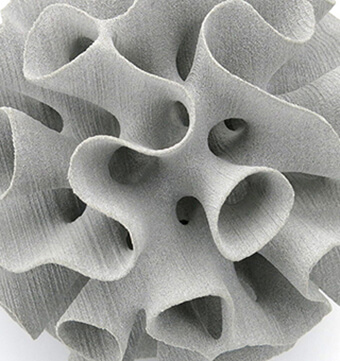

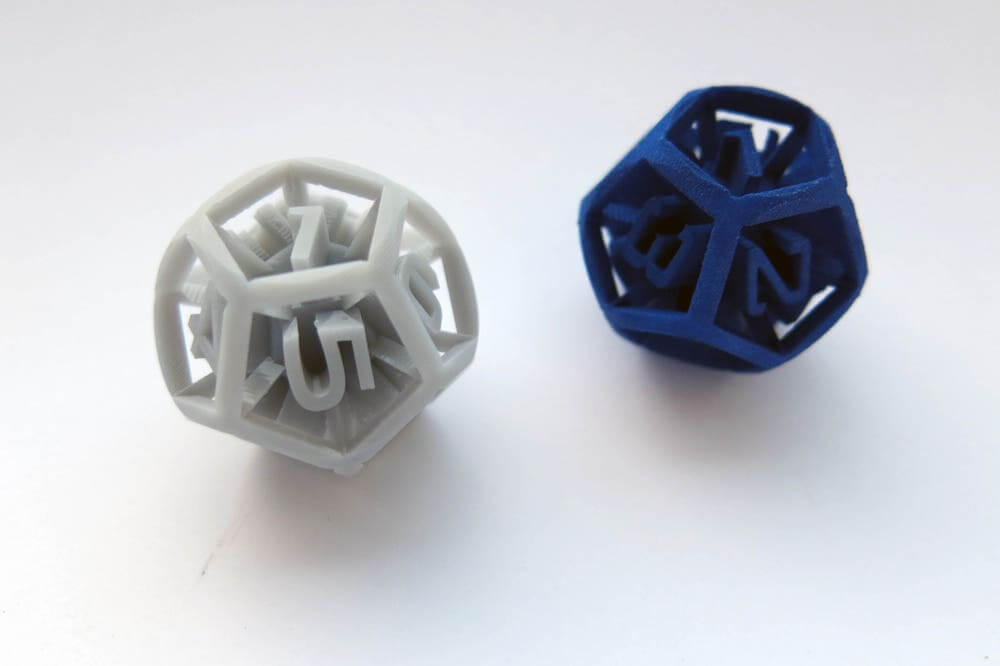

Selective Laser Sintering process is a powder-bed technology, in opposition to some 3D printing methods such as FDM or SLA, you don’t need to create support structures for your parts. The powder will act as a natural support, less chance of damaging the intricate interior geometries that 3D printing is capable of making because the support structure doesn’t need to be removed.

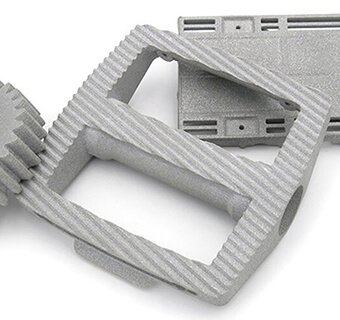

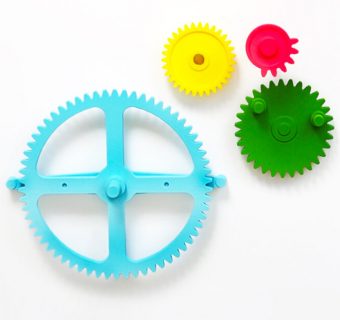

Freedom of design, just like for any 3D printing process, is an important part of using SLS. From perfectly optimized parts to all-in-one assemblies, you can build the best version of your project with this powder-bed technology.

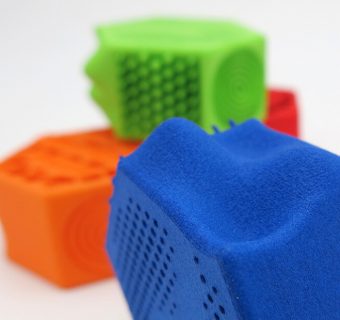

SLS 3D printing gives you access to a large variety of material as well as many finishings achieving high-quality surfaces for your end-use components. On-demand manufacturing is a real opportunity to adapt your production to demand. You will be able to avoid minimum order quantities, perfect for limited editions or series production. Moreover, the accuracy and consistency of the parts printed with SLS makes it an ideal manufacturing choice for the production of large quantities, or series.

One of the strength of this industrial manufacturing process is also the possibility of making complex geometries as long as you respect the design guidelines. Also, while using Selective Laser Sintering you benefit from interesting mechanical properties, allowing to produce functional parts or prototypes.

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook