Views about 3D printing

Along with the State of 3D Printing 2022, Sculpteo conducted a study to get a better understanding of point of view of 3D printing users about 3D printing and sustainability.

- 81% of the respondents have goals in terms of sustainability, establishing that a significant majority of companies are determined to improve their processes and are ready to take action.

- 59% think that a more prominent offer regarding sustainable materials could improve the sustainable development of 3D printing.

- 61% find that on-demand manufacturing is a sustainable advantage.

Get our complete study, to understand the point of view and needs of 3D printing users regarding sustainability.

What are the sustainable advantages of 3D printing?

A product that couldn’t previously be produced can now be designed with the freedom provided by 3D printing. The emphasis switches from creating a part that can be produced to creating a part that can be printed and is sustainable within that. The design procedure allows for the addition of lattice structures or the removal of unnecessary material from the model.

Freedom of Design can also allow for designing integrated parts, allowing to skip most of these steps by directly printing the needed part in one go, saving material, time, and money in the process.

Additive manufacturing is also a way to avoid stocking problems and overproduction. Businesses are often owning huge inventory warehouses, where spare and overproduced parts are stored. The physical inventory obviously costs money for energy, labor, and so on. Moreover, depending on how long the parts are kept there, they may deteriorate or/and no longer be usable which result into a waste of both material and energy.

Additive manufacturing offers a solution to this problem: digital inventory, or on-demand production. If a part is needed, it can simply be printed on demand and then sent to the customer. This does not only help to fight overproduction nowadays but also is exceptionally cost-effective and more efficient.

One of the biggest advantages of 3D printing is mass customization and the possibility to create spare parts quite easily. Indeed, mass customization is ideal when a manufacturer needs to find parts that are no longer produced. The create of spare parts with additive manufacturing can be included in home appliances production, automobile restoration, or even for tooling and any kind of machine.

With this practice, fewer products have to be disposed of. And less raw material has to be used to produce brand new product.

- Bio-based and renewable materials

The ultimate goal of the 3D printing industry in terms of material would be to create an even larger offer of renewable materials.

HP PA11 or Ultrasint® PA11 are the most reliable solutions for your industrial projects. PA11 is a bio-derived powder with exceptionally high toughness. This material has the particularity of offering high ductility and impact strength for all applications. If you need durable parts able to withstand high mechanical loads and stress, then PA11 is a great option.

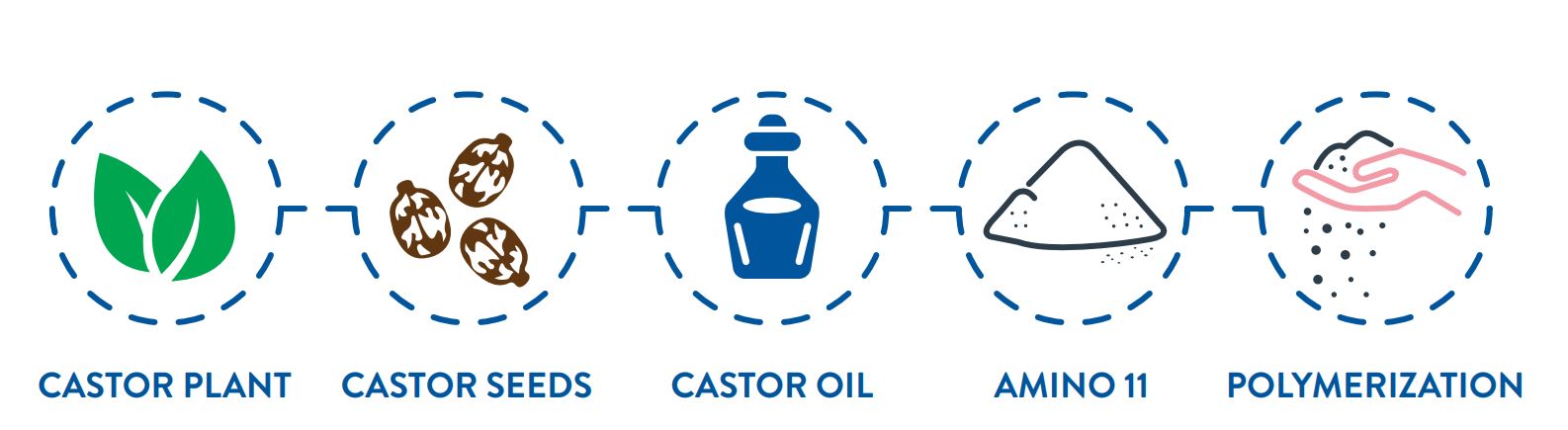

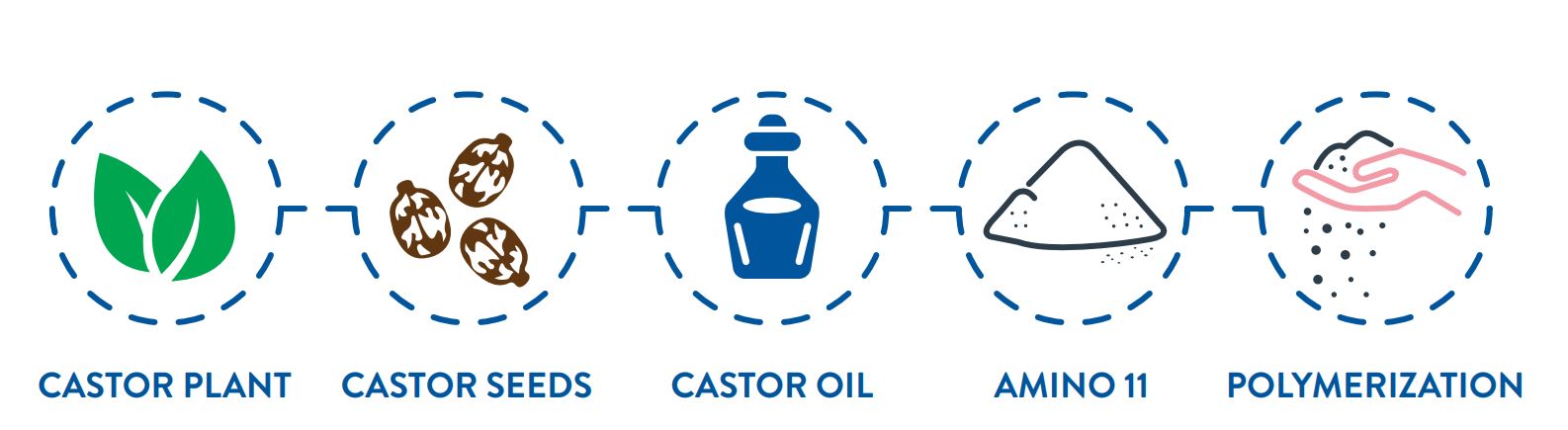

PA11 is based on 100% renewable biomass sources. The Castor seed is extracted from the castor plant to make oil. The oil is then converted into the monomer (11-aminoundecanoic acid), which is finally polymerized into Polyamide 11.

Get an instant SLS 3D printing quote for your PA11 project right now.

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook