Another important difference between objects printed with SLS and SLA printers is how they behave mechanically. Just as we said on Resolution, here we can only generalize and describe the most commonly used materials for each technology.

SLS printers can use a wide range of materials, always powdered materials, but most often they are polyamides (typically, Nylon PA12) that can have additives to change properties such as color, strength, flexibility, stiffness etc. You may think you don’t know this material but most definitely its commercial name will ring a bell: it’s just Nylon, a fantastic all-rounder that offers durability, strength and extraordinary abrasion resistance among other characteristics.

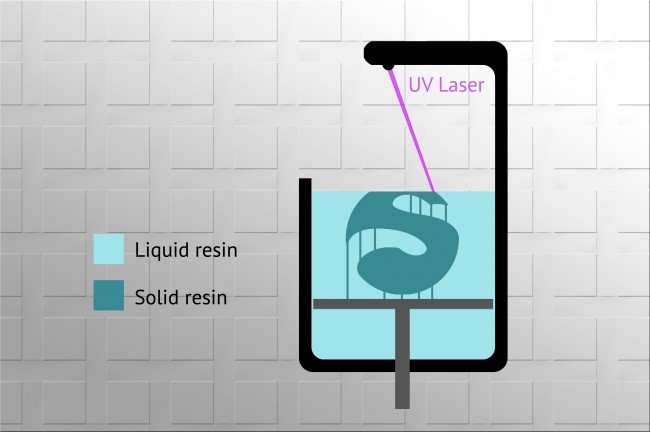

For SLA 3D printers, typically the manufacturer will offer their own resins but there is a wide range of third-party options available that are usually cheaper. Generally speaking, they tend to be significantly more rigid and thus brittle than Nylon although new compounds are being released all the time, with softer and more flexible characteristics, quite similar to rubber material.

One significant difference of resin objects compared to Nylon is their behavior under load. Rigid resins tend to fail violently crashing in multiple pieces while Nylon has a wide elastic region under load (where can still return to its original shape) followed by permanent deformation and finally failure. The choice between SLS vs SLA 3D printing will totally depend on the nature of your project

What about the surface?

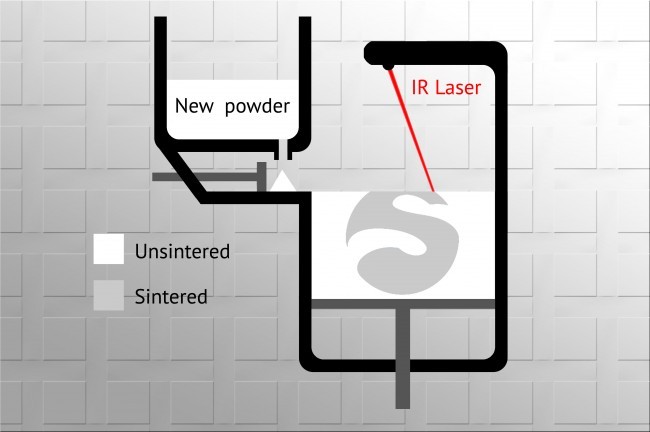

Here it comes one of the most noticeable differences at first sight. Using a SLS printer, the sintering process intrinsically creates a porous solid material, as the air that was originally within the powder goes to create microscopic air bubbles on the sintered material.

Although this is nothing you can see with your naked eye, it feels slightly “rough” when touching it. On the other hand, polymerizing a liquid substance creates a solid homogeneous bulk of material.

PreForm Support designed by Formlabs to minimize its impact on the print. Credits: Formlabs.

Colorwise, polyamide powder is offering basic option: black and white, for raw material options. A third option could be gray by mixing those two, but one could say that the offer is rather limited, with no option for translucent or transparent SLS prints. Resins printed using SLA machines allow for other options, while mixed with color pigments.

Supports during the 3D printing process

For objects that either do not have a clear standing position (e.g. a ball) or they do but they have overhangs (e.g. the shade of a table lamp) support material or structures are required for almost all 3D printing technologies, with SLS printers being one of the few exceptions, thanks to the unsintered powder acting as support material all around the object being printed during SLS process.

Depending on each particular case, sometimes the user can dismiss or minimize the use of support at the expense of quality on the trickier areas, but this is a trade-off that is always there when using SLA printers. When support structures are used, the printed part will require some manual cleaning time and even then, is not uncommon to end up with “scars” on the spots where it was removed.

Unfortunately, using a secondary support material is not an option with SLA process as all the building material comes from a single spot, resulting in both the object and its support structure made out of the same material.

Post-processing for SLS and SLA technology

Although both SLS and SLA prints have post-processing options, they are usually different because the prints are different by themselves, but you get some really good surface finishes.

- Polishing: SLA prints are smoother and shinier, so polishing is mostly unnecessary. For SLS prints, it can be an interesting option if a smoother, shinier aspect is required.

- Colors: SLS 3D printing is offering a wide range of color possibilities on our online 3D printing service.

- Trimming/Cutting/Gluing: Both polyamides and resins are suitable for some hand manual work, always using the right tools. You can learn more about this on our 3D printing blog.

Food and chemical compatibility

Food containers are probably not on the Top-10 list of 3D printed objects but being food compatible and biocompatible as is the case with our plastic (polyamide 12) material definitely does no harm (but remember that this may not be the case for dyed polyamide!). On the SLA world, biocompatible or food approved resins are not that popular, especially not for consumer-grade printers, but it is still possible to find and buy them from specialized providers (generally related with medical applications).

SLS Nylon objects can also withstand some solvents like Acetone, some types of alcohols among others, you can check the list on our plastic material page. For resin materials, you will need to refer to the specifications of each individual product as it can vary significantly.

Cost

Because SLA printers are “cheap” in comparison with professional SLS printers, one could think that SLS prints should be more expensive too. In reality, thanks to the fact that Nylon is such a common material outside the 3D printing circle and that SLS printers can often output extremely large quantities in a single run, SLS prints are usually cheaper than SLA prints. That is, of course, if you don’t have to buy the printer, otherwise, SLA would most likely be cheaper, even if consumables are relatively expensive afterward.

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook