Resin 3D printing is commonly used in industries such as medical and dental, consumer goods, jewelry, and more. It is also used in the production of prototypes, end-use parts, and molds for casting. Polyjet is not the only resin-based technology. For example, here are the different options you can use by working with Sculpteo’s online 3D printing service:

One of the earliest 3D printing processes ever created is stereolithography (SLA). In this method of additive manufacturing, resin material is 3D printed using a photochemical process.

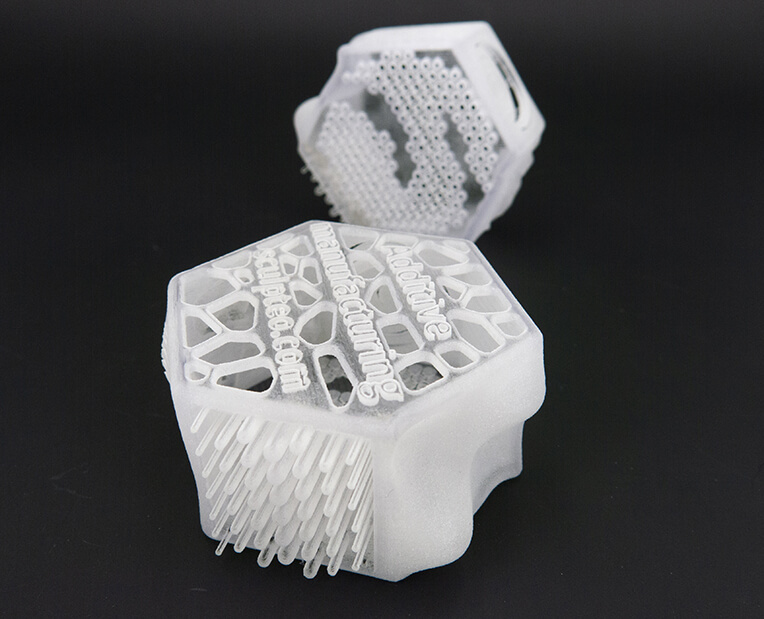

This SLA 3D printing process cures the liquid photopolymer resin in a vat. When the build plate is moved incrementally, the liquid polymer is exposed to light, and the UV laser exploits this exposure to generate a cross-section. Up till a model is created, this layer-by-layer procedure is repeated. The liquid, uncured resin at the bottom of the container can be utilized to build the object’s next layer when the bottom-up object is removed from the resin.

The resin tank flashes entire layers at the UV light source, which is an array of LEDs shining through an LCD. The entire image is hidden behind a screen so that only the layer that has to be cured is visible. A cost-effective resin production method for large, intricate functional parts is LCD 3D printing. Thanks to 3D printers with larger build trays created by companies like Photocentric, this 3D printing technique concentrates on mass production and large component 3D printing for resin materials.

The light source for DLP 3D printers is a digital light projector. A semiconductor chip matrix with tens of thousands of micromirrors makes up the DMD (Digital Micromirror Device). The digital light projector’s projected light beam is navigated by these micromirrors.

CLIP is a printing technology developed by Carbon. It works by projecting a continuous sequence of UV images, generated by a digital light projector, through an oxygen-permeable, UV-transparent window below a liquid resin bath. The dead zone created above the window maintains a liquid interface below the part. Above the dead zone, the curing part is drawn out of the resin bath.

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook