Any 3D printing material can create textures on parts, but depending on your project and objectives, certain materials will be more advantageous than others. To help you get started, we’ve highlighted some excellent materials for highly detailed textures, strong mechanical properties, and general texturing. Consulting the design guidelines for each material or your design team for additive manufacturing is always recommended; you can request more information from our Design Studio team for the best texture, material, and design for your specific project and needs.

Resin Material

For a high level of detail, superb surface finish, and incredible accuracy, turn to resin 3D printing material. These materials are the perfect solution for creating injection mold-like prototypes or aesthetic parts for high fashion, for example. If the main objective of your part or project is to show details and complex geometries, resin materials are a perfect choice.

Want to learn more about this highly detailing and smooth material? Check out our Ultimate guide for 3D printing resin.

TPU Flexible Material

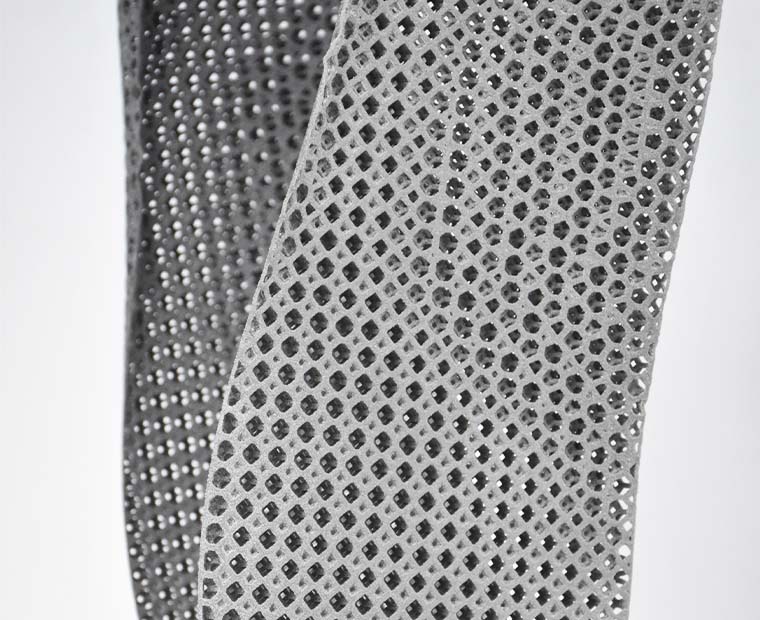

TPU is especially suited for lattice structures and creating flexible surfaces; it is the perfect manufacturing material to benefit from great design freedom. Creating complex geometries and intricate designs is possible and a significant advantage of this material. With TPU, 3D printing will help you get parts with varying flexibility. Depending on the different requirements within a part, you can have varying zones of thickness and flexibility. It is also possible to create flexible lattice structures to help develop orthopedic midsoles. What is TPU: Everything you need to know about these flexible materials.

We offer two TPU materials below:

- Ultrasint TPU01 – Thermoplastic Polyurethane Powder for HP Jet Fusion Printers; this material offers durable, strong, and flexible parts. MultiJet Fusion TPU is a perfect 3D printing material choice if you need to produce parts requiring shock absorption, high elasticity, and energy return. For flexible lattices and complex parts, this material is ideal.

- Ultrasint TPU 88A – Offers a resistant, flexible, and rubbery material finished part for a variety of applications. With good resilience after deformation and high UV stability, this SLS TPU offers numerous advantages for your projects requiring an elastomeric material. Offering good hydrolysis resistance, great shock absorption, and a smooth white surface.

General Texturing to hide 3D printing layering or surface imperfections

In general, Selective Laser Sintering (SLS) and Multi Jet Fusion (MJF) technologies are great for creating textures and complex geometries for consumer products, architectural models, drones, robotics, special machinery, jewelry & watches, IoT devices, sports equipment, footwear, orthopedic technology, education, electronics housing, medical devices, sculptures, jigs and fixtures, promotional items, and more. These additive manufacturing technologies are a good choice for functional prototyping to production and can easily produce the textures and patterns necessary for each project’s objectives.

Are you ready to use texture for your next 3D printing project? Get in touch with our Design Studio to learn more about your individual projects’ full additive manufacturing potential.

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook