To laser cut, wood can involve the use of either MDF material or Plywood material. Both materials are made out of several layers of wood, making them strong materials capable of handling the laser’s output. Below, you can find a summarized description of both wooden materials.

Medium-Density Fibreboard (MDF)

MDF is a wooden material that consists of residues from soft- and hardwood. These residues are then stacked together with wax and resin binders. To top these wooden fibers up, wooden panels are attached with pressure. These panels give the MDF material its light beige panel color and fine texture look. These panels also allow for qualitative painting jobs. The benefit of MDF is, that due to the mix of wooden fibers, there is no chance of the wood to split because the material has the same properties all over the place. MDF is also inexpensive due to it consisting of wooden residues which are basically processed unused scraps – costing only a small percentage of the actual wood it originated from.

Plywood

Whereas MDF consists of layers of wooden fibers, Plywood consists of wooden sheets that are glued and pressured onto each other. The layering is visible due to the alternating wood grain caused by differentiating sheets of wood. These differentiating layerings offer many benefits for the material itself such as water resistance and flexibility. As for our plywood at Sculpteo, we have the following suboptions of wood for you to choose from Poplar plywood, Okoumé plywood, Ceiba Wood, and Maple plywood. Each option has a different layering giving your parts a unique look. Click here to find out what the differences are and which one suits your possible future project to laser cut wood best!

The best laser cut wood projects

Of course, there are already companies and engineers out there that made use of laser-cut wood or laser engraved wood! Below you can find some examples and make you see for yourself why using laser cut wood was beneficial for that specific product or project:

Laser cut business cards

In the past, we’ve already mentioned laser-cut business cards in a blog post but Studio eQ takes it to a whole different level. By using premium woods like Veneer plywood, Studio eQ laser cuts company logos and graphics in the neatest way possible. The company, by laser cutting cards, takes business cards to a different dimension in card design – allowing companies to stand out from others.

Source: Studio eQ

Complexly layered laser-cut bracelets.

Artist Anthony Roussel was inspired by the seaside coastlines and by modern architecture when he made these bracelets. The designs of these bracelets are very complex and highly detailed, something that could only have been achieved by a laser beam’s precision – and not with other traditional manufacturing methods.

Source: Anthony Roussel

Laser-cut jewelry components

The Lucas Laser Workshop creates wooden gifts and home decorations made with laser cutting. These products are custom designed using only natural elements and natural woods.

Source: The Lucas Laser Workshop

Laser Cut wooden lamp

The Stanford Product Realization Lab is a teaching lab meant for Stanford students to try out their own innovative ideas. One student made this wooden and curved lamp. The outside of this lamp was laser cut out of wooden materials. The kerf’s pattern includes slits that allow the panel of wood to be flexible and to be able to thus bend. The bending allows for a curve giving this lamp its unique design.

Source: The Stanford Product Realization Lab

Laser cut bamboo bookmarks

Little Card Boutique is situated in Australia where they sell these very unique personalized custom bookmarks made out of bamboo. Yes, we know bamboo is technically not wood but when pressed together, it has the same look and feel as wood and it can even be stronger than oak! These bookmarks are laser cut and they can be personalized with name tags and with unique designs, all implemented by a laser engraver.

Source: Little Card Boutique

Laser cut wooden logo signs

These wooden signs made by Tigermouse Design can be perfectly placed in offices to show their brand design or logo with a unique twist: the words can be in negative space! This requires extreme precision while cutting, which again can only be achieved with a laser beam.

Source: Tigermouse Design

Unique wooden bathroom signs

Living in a time where more pressure is put on creating a unique (office) space, it is ideal to laser cut creatively designed bathrooms signs. Company Grayskunk knows how to put a different spin on traditional gender roles in bathroom signs with a laser cutter.

Source: Grayskunk

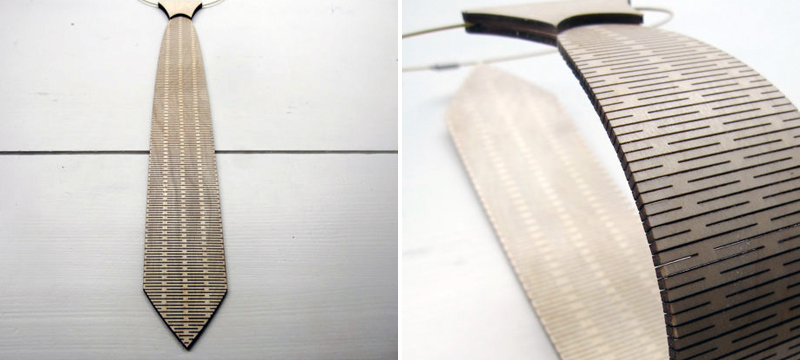

A laser cut wooden tie

Yes, even in the fashion industry wooden materials can be implemented along with a laser cutter! This wooden tie of 3.2mm thick is designed by CreativeUseofTech and made from Birch plywood. This designer really makes you think about the use of technology in different ways than you might originally think of.

Source: CreativeUseofTech

The organically shaped living room lamp

This incredibly shaped lamp was designed by Etsy seller Lampshapers. It is 6mm thick and made from MDF material. Whereas this would take ages to manufacture with regular manufacturing methods, laser cutting really made short work of it. Another great example of a laser cut object meant for home decor.

Source: Etsy – Lampshapers

Original laser cut wooden packaging

Although a bit more targeted towards a niche, hipster market – the packaging of this six-pack beer case from Etsy designer nygaarddesign makes an amazing laser cut gift for beer lovers. It is 5.2mm thick and made out of Birch Veneer. The packaging itself can then be laser engraved with your company logo or with name tags. With packaging, you can truly cut and engrave your heart away!

Source: nygaarddesign

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook