Both CNC machining and printing have their advantages and disadvantages. As with many tools and techniques, there often isn’t a single “better” system. Rather, the best tool for the job will depend on what the job is and what qualities the tool has to offer.

Here are some of the key differences between the two technologies:

1. Accuracy and Precision

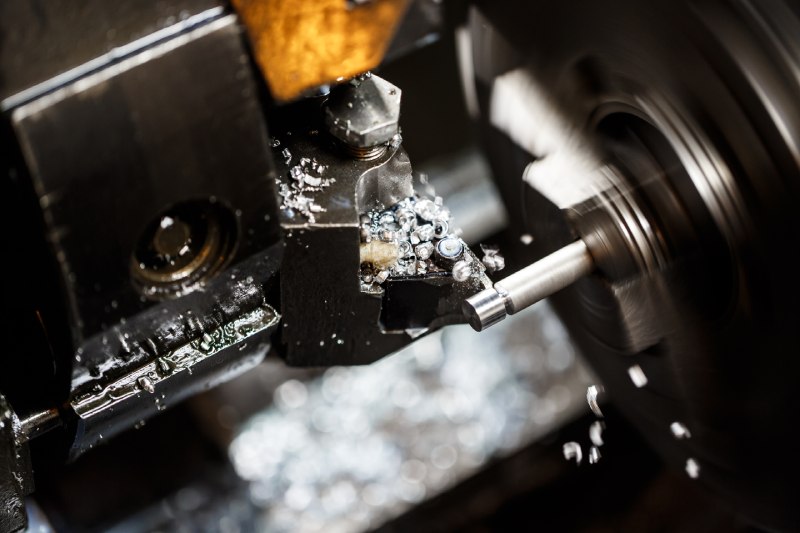

CNC machines are known for their accuracy and precision. They can produce parts with extremely tight tolerance and repeatable results. CNC machines are often used in industries where precision is critical, such as aerospace and medical manufacturing.

While modern 3D printers are capable of producing objects with high levels of detail, they might not always be as accurate as CNC machines. This is why it is important to understand when to use CNC Machining, and when to use 3D Printing, with CNC Machining providing an overall greater accuracy.

2. Lead Time

CNC machines are faster than 3D printers when it comes to producing parts; they can produce parts in a matter of hours, whereas 3D printers can take days or even weeks to produce the same parts.

However, additive manufacturing has an advantage when it comes to lead time for prototyping. CNC machining requires a lot of setups, which makes switching between different products costly. Printing does not require much setup, making it much faster to go from one product to another. Because 3D printers can create objects quickly and inexpensively, designers can rapidly prototype multiple iterations of a design before finalising it for production. This ability to quickly iterate and refine designs can significantly reduce development time.

3. Cost

The cost of CNC machining depends on a variety of factors, including the complexity of the part, the type of material used, and the amount of time required to produce the part. CNC machining can be expensive, especially for small runs of parts, though it can be very cost effective for large runs.

3D printing, on the other hand, is relatively inexpensive when considering the cost of an individual part or workpiece. This is because 3D printers build parts layer by layer, and the cost is largely dependent on the amount of material used, not the setup. This makes 3D printing an attractive option for prototyping and small production runs.

4. Materials

CNC machines can work with a wide variety of materials, including metal, wood, and plastic. They can produce parts that are strong and durable, making them ideal for applications where strength and durability are critical. However, they produce a lot of waste, since the manufacturing process is, by nature, subtractive.

3D printing, on the other hand, with its additive nature, is allowing for precise control over the amount of material used. This means there is less material waste than with CNC Machining. 3D printing can also work with a variety of materials, but the range of materials is more limited than with CNC machines. 3D printers are typically used with plastics, resins, and a few metals.

5. Applications

CNC machines are used in a wide variety of industries, including aerospace, automotive, and medical manufacturing. They are often used to produce high-precision end-objects, with complex geometries that would be difficult or impossible to create with current printing technologies.

Conversely, additive manufacturing is undoubtedly optimal to create unique and complex shapes that would be difficult or impossible to achieve with more traditional manufacturing processes. 3D Printing is ideal for prototyping and small production runs, and is also allowing for the production of quality end-objects, in industries such as architecture, fashion, and product design.

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook