Both Inventor and Fusion will give you a highly advanced experience with interesting functionalities. You can perform stress tests, simulations, or get the necessary documentation. If you’re planning to 3D print your models, they will also allow you to prepare the files.

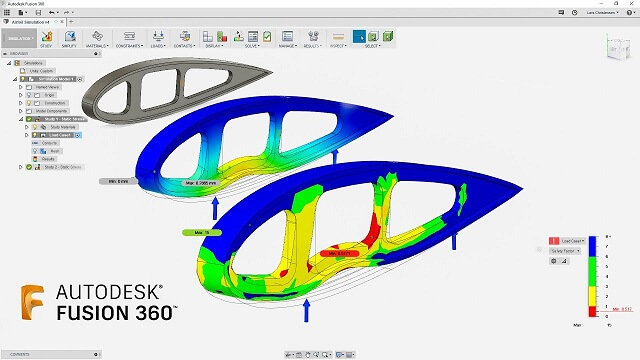

The tools of Autodesk Fusion 360 allow for precise 3D modeling, rapid prototyping, generative design, and manufacturing. You can determine usability before the production to catch as many potential failures as possible. You can test different alternatives for your design and find new, innovative solutions. Additionally, you will have access to premade 3D models such as gears os screws.

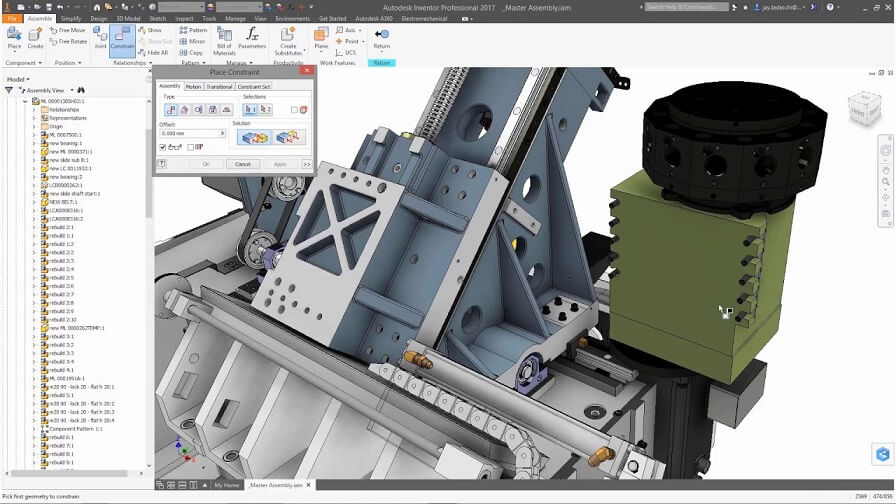

Autodesk Inventor will provide you with high-performance, engineering tools allowing you to produce accurate mechanical parts. You will also be able to gather documentation and perform simulations and tests to prepare your model for production. Simulation in Inventor is a real advantage. The program offers the opportunity to perform dynamic simulation and stress analysis on the parts you’ve created as well as large assemblies. This is perfect to anticipate how your product will perform in real-life and improve your iteration process. Some of these powerful tools will allow you to enable rapid assembly configurations or design specifically for sheet metal and frames. You can also choose already standard components from a library.

Design automation is also a big advantage provided by Autodesk Inventor. Using iLogic, the design can apply automation rules to assemblies.

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook