One of the significant advantages of Laser Engraving is the many different materials that can be used. No matter if it’s acrylic, plywood, MDF, cardboard, glass, metal, leather, or POM, Laser Engraving can be used on all of them. Let’s take a closer look at how this technology is applied to each material:

Acrylic

The plastic material acrylic has many characteristics. It is strong, considerably resistant to scratches as well as stable concerning tolerance and shrinkage. This material copes well with laser operations and will deliver a good outcome. Due to its waterproof properties, it is a great asset in the kitchen or bathrooms. Different industries are already using acrylic, like medical or electronics.

Two acrylic types are distinguished: cast acrylic (GS) and extruded acrylic (XT). However, in a laser engraving process, only cast acrylic is recommended, as it produces better results.

At Sculpteo, we offer over fifteen different acrylic colors.

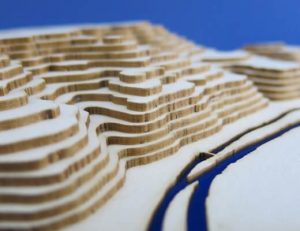

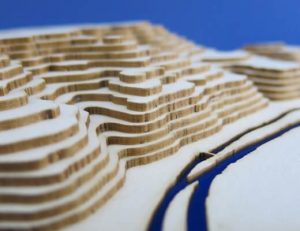

Plywood

Plywood is another material that can be laser engraved, but what exactly is Plywood? This material is made by gluing several sheets of wood together. It is often used by cabin makers, builders, or industrial designers who rely on Plywood’s impressive characteristics like flexibility, water resistance, mechanical resistance, lightness, and aesthetic appeal. This material also has a clean and light surface which makes it perfect for laser engraving projects. As a lightweight material with a low chance of snapping, it is a good option for assembly projects.

In most cases, Plywood is used to give a design a unique but natural appearance. Therefore it is an excellent material for finished goods.

MDF

Another wood material that can be used is MDF, short for Medium-Density Fiberboard. This engineering wood material is produced from hardwood or softwood residual fibers, then combined with resin binder and wax. MDF panels are formed when the fiber is applied with high temperature and pressure. MDF is suitable for engraving as it allows to create depth within the material.

Like the materials before, MDF has many impressive features: it is robust and very affordable. Plus, its post-processing is easy as it is waterproof and fireproof, can be molded and curved, painted, stained, and dyed. MDF is defined by its fine texture and light beige color.

A box made out of MDF

Cardboard

Cardboard is from the same origin as regular paper and is a rigid and light material. In the production process of a cardboard flat, embossed or corrugated paper is laminated into different thickness parts. Cardboard is not only recyclable and biodegradable but also extremely lightweight and priced competitively. The belief that cardboard is only used for packaging is not valid, as it is an excellent option for prototyping or is used in the architecture field for presentational models. Another perk of using cardboard is that it is super easy to work with. It can be folded, cut, and works with different assembly methods such as glue or staples.

An object made out of cardboard

POM

POM stands for Polyoxymethylene and is an engineering thermoplastic. It is also known as Acetal or Delrin. Due to its excellent mechanical properties, outstanding dimensional stability, and strong resistance, it is extremely popular. The surface of POM is smooth and resembles glass.

This material offers various properties. It is not only lightweight, robust, and durable, but also water- and weatherproof and solvent resistance. It is often used for industrial tooling, spare parts, gears, hinges, or locks.

Glass

Almost every type of glass can be engraved. With this technology, mugs, wine glasses, or bottles, or other items can receive incredible effects. Especially in the wine industry, laser engraving is often used to give the items a more custom look. However, there are a few things to be aware of: It is essential to use the right glass. That is why it is always helpful to test the type of glass first before the engraving process starts.

Metal

Like glass, almost every metal material can be engraved, steel, iron, silver, aluminum, gold, silver are one of the most common ones. While glass engraving is most commonly used for promotional purposes, metal engraving is used for promotional and industrial purposes. Aircraft companies will engrave their wings for better aerodynamics, automotive companies work with laser engraving to manufacture certain parts, and others engrave barcodes or QR codes onto their parts.

Leather

Among metal, glass, plastic, and wood, is leather, another material that can be laser engraved. for a unique and custom look. The following leather materials are most often used: Suede, Alcantra, Natural, Synthetic, and Nubuck. Leather is generally quite hard, which makes laser engraving even more appealing, as it is tricky to create visually appealing designs using other tools.

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook