The best materials to 3D print your prototypes at Sculpteo

The choice of your 3D printing material really depends on your project. Here is a selection of our most used materials for prototyping projects! Plastic materials are obviously the cheapest solution for this stage of your product development; let’s see what you can do with them.

This white plastic material is one of the most affordable materials with a lot of great mechanical properties. This material is made from fine polyamide powder, and is perfect for both prototyping and production. It will create your parts thanks to the Selective Laser Sintering technology.

If you choose this material for your prototyping project, you will see that you will have the choice between various options and finishes, but you can also get raw parts. Prototyping with Nylon PA12 (plastic) is a good solution because this 3D printing material is one of the cheapest options, so you will be able to make many iterations with a resistant material, that gives you a lot of freedom in terms of geometry.

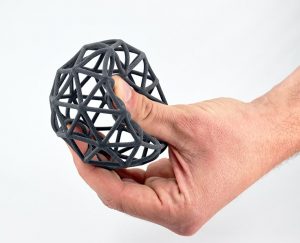

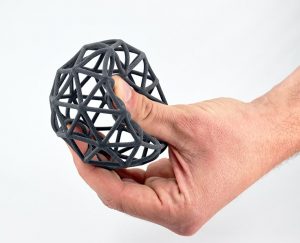

Our Multi Jet Fusion PA12 is a grey plastic. This material is perfect both for prototyping and production and its raw version is clearly the cheapest option you will get! It will allow you to make many iterations at a lower cost. The objects printed with this material are well suited against scratches and abrasion, which could be great to make tests. It is also light stabilized, U.V. stabilized and stable to weather, which is perfect if you need to make an experiment in outdoor conditions.

This resin is specifically developed to prototypes and is well suited for non-functional prototypes. Indeed, if you need to manufacture highly detailed parts this material will be the perfect option. Prototyping resin offers a smooth surface finish, quite similar to objects manufactured using plastic injection molding. This resin is 3D printed using the Stereolithography (SLA) process.

Fused Deposition Modeling techniques are particularly useful in the development of prototypes. Using this option, you will not get the most detailed prototypes. However, for some oversized project, this technique can be interesting. Indeed, at Sculpteo, we are using BigRep 3D printers to 3D print our PLA filament, allowing to print parts with the maximum size of 1 x 1 x 1 m.

You need a really flexible plastic for your 3D printing project? TPU will be the perfect solution for you. This rubber-like material has a high elasticity and a high strength. That could perfectly fit your project if you need something really flexible for fully functional prototypes. As this material creates parts really resistant to stress and fatigue, it can even be used for your final products. Think about it! On our online 3D printing service, you will have the opportunity to choose between two TPU: Ultrasint® TPU01 and Ultrasint® TPU 88A.

- 3D printing metal for your prototypes ?

If you are planning to create 3D printed prototypes with metal materials, you have to know that it is totally possible but that it is not the most economical option for you. However, we recommend you to use our Ultrafuse 316L Stainless Steel if you need to manufacture metal prototypes. This affordable material is printed using FDM technology; it is resistant and can be used to run tests of functional prototypes.

Binder jetting technology, can also be used to print your prototypes parts, with Steel / Bronze 420SS/BR and Stainless Steel 316.

Keep in mind that Direct Metal Laser Sintering is also used to make prototypes for the aerospace industry using Titanium 6AI-4V but is not a cost-efficient method for prototypes. It’s good to know if you have such projects, but most of the time, plastic will be used as the most convenient material for prototypes.

We hope that this article helped you to understand all the benefits and possibilities offered by additive manufacturing to develop prototypes. Do you have more questions about these materials? Feel free to contact our sales team for more information.

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook