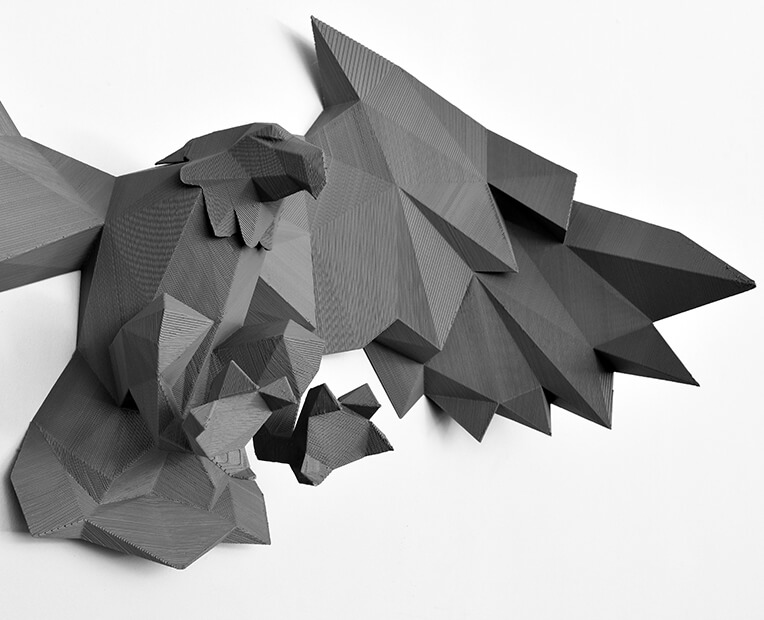

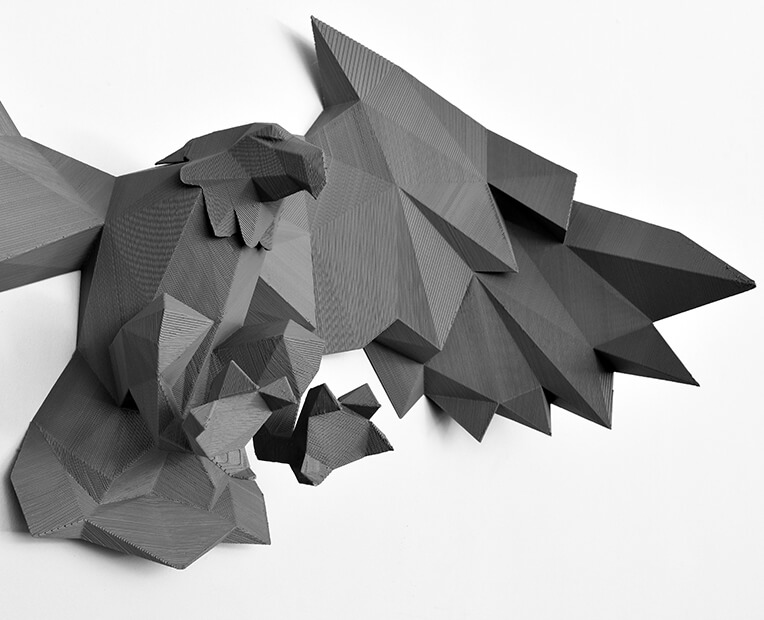

Polylactic acid, also known as PLA plastic, is a type of vegetable-based plastic that typically starts out as cornstarch or sugarcane. Fermented plant starch is typically used to create the monomer. The primary natural raw material utilized in 3D printing is this thermoplastic aliphatic polyester. PLA is one of the most widely used materials for additive manufacturing for the production of filament among all 3D printing materials.

At Sculpteo, PLA material is printed using BigRep 3D printers and mainly used to manufacture big parts up to 1x1x1m.

The most environmentally friendly PETG-based filament on the market is probably the rPET filament. This environmentally friendly PETG filament combines strength and toughness with printability and is available in a variety of colors.

ABS (Acrylonitrile Butadiene Styrene) is part of the thermoplastic polymers family, it is actually a common thermoplastic polymer. Just like PLA, ABS is widely used for FDM 3D printing. As its name implies, ABS is created from Acrylonitrile, Butadiene and Styrene polymers.

Ultrafuse Stainless Steel 316L is a new industrial-grade metal filament for professional uses. Created by BASF, Ultrafuse 316L filament is composed of 90% stainless steel and 10% polymer binder which allows it to be used in any FDM/FFF printer.

The material is characterized by its impressive mechanical properties and low cost of production, making it one of the most affordable materials for metal 3D printing.

Ultrafuse® 17-4 PH is a metal filament, made for the creation of metal components in 17-4 PH stainless steel. This Ultrafuse® 17-4 PH material is characterized by its impressive strength. It is also one of the most affordable materials for metal 3D printing.

17-4 PH and 316L are among the most used stainless steel materials, however, these two materials present different properties regarding their tensile strength, yield strength, elongation at break, and hardness.

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook