Let’s start by looking at the benefits of 3D printing.

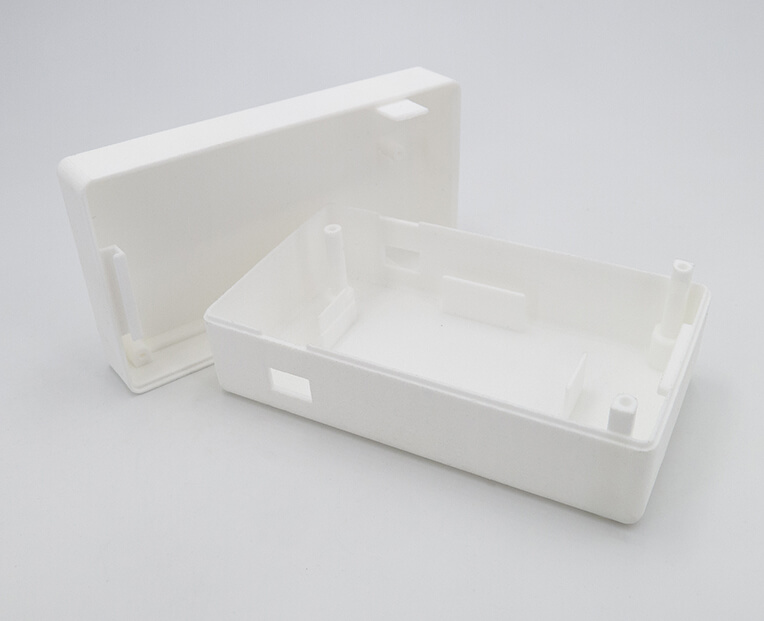

Faster Time to Market

One of the more significant advantages in consumer goods manufacture is the fact that it allows for rapid prototypes to be created and product iteration, enabling companies to bring new products to market more quickly than with traditional manufacturing methods. Traditional processes can take weeks or even months to produce a prototype, and involve much more expense in tools and materials. In contrast, 3D printing can create a prototype in a matter of hours, and cost far less in terms of the tools and materials needed to do it. This rapid prototyping also allows companies to iterate on product designs more quickly, making changes and refining designs until the product meets the desired specifications.

Customization

There is more to bringing a product to market than just creating it, of course. Another significant advantage of 3D printing consumer goods is mass-customization, the ability to create products that are tailored to individual customer needs and preferences much easier and cheaper than with traditional methods. With 3D printing, it’s easy to create products that are customized to specific dimensions, shapes, colors, and even materials, offering greater flexibility and product variety. This can help companies differentiate themselves in a crowded market and build customer loyalty, as customers are more likely to choose a product that is unique and tailored to their specific needs over generic products that might not be quite the right fit for them.

Reduced Waste

Being an additive manufacturing process, it produces less waste than traditional methods, making it a more sustainable choice for companies looking to reduce their environmental impact. Traditional manufacturing processes often involve a high degree of material waste, as products are cut, stamped, and moulded from larger pieces of materials, which generates significant amounts of waste. In contrast, 3D printing produces products layer by layer, using only the required amount of material, reducing waste and making it a more sustainable option. Additive manufacturing in consumer products is a powerful way to help protect the environment, as well as bring manufacturing costs down.

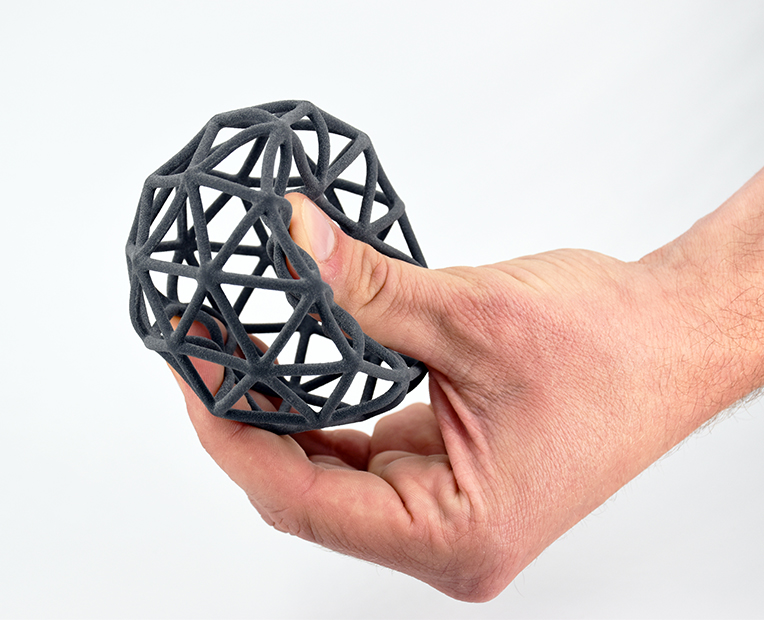

Complex Design Capabilities

3D printing allows for the creation of intricate and complex designs that would be difficult or impossible to achieve using traditional manufacturing methods. It enables companies to create unique shapes, textures, and patterns, opening up a range of design possibilities for consumer products. This can be particularly beneficial in the creation of high-end products like jewellery or fashion accessories, where design complexity is a selling point.

Lower Costs for Small Production Runs

When producing large quantities of a product, the cost of machinery and setup can be worth it for the eventual savings, but this doesn’t scale down to smaller production runs. 3D printing, on the other hand, can be a cost-effective option for small production runs, as it does not require those high set-up costs. Using this process, companies can produce a small number of products at a lower cost, which can be particularly beneficial for companies that are just starting up, have limited budgets or want to rapidly prototype or do limited runs of a product.

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook